Volvo Wheel Loaders

VOLVO WHEEL LOADERS L60H, L70H, L90H

13.0-18.3 t / 24,250-38,140 lb 165-184 hp

DOWNLOAD VOLVO WHEEL LOADERS BROCHURE

A passion for performance.

At Volvo Construction Equipment, we’re not just coming along for the ride. Developing products and services that raise productivity – we are confident we can lower costs and increase profits for customers around the globe. Part of the Volvo Group, we are passionate about innovative solutions to help you work smarter – not harder.

Helping you to do more

Doing more with less is a trademark of Volvo Construction Equipment. High productivity has long been married to low energy consumption, ease of use and durability. When it comes to lowering

life-cycle costs, Volvo is in a class of its own.

Designed to fit your needs

There is a lot riding on creating solutions that are suited to the particular needs of different industry applications. Innovation often involves high technology – but it doesn’t always have to. Some of our best ideas have been simple, based on a clear and deep understanding of our customers’ working lives.

You learn a lot in 180 years

Over the years, Volvo has advanced solutions that have revolutionized the use of construction equipment. No other name speaks Safety louder than Volvo. Protecting operators, those around them and minimizing our environmental impact are traditional values that continue to shape our product design philosophy.

We’re on your side

We back the Volvo brand with the best people. Volvo is truly a global enterprise, one that is on standby to support customers quickly and efficiently – wherever they are.

We have a passion for performance.

A Strong, Dedicated, Capable Dealer Network

Our dealers are strategically located throughout North America to provide the equipment you need and the parts and service support you demand for a productive and profitable operation.

The strength of our dealer network is enhanced with extensive individualized product support training at our best-in-class Customer Center in Shippensburg and through hands-on training. Using a great Product Demonstration Center featuring a dedicated area for most commons applications, visitors operate equipment from our entire product line under a variety of simulated working conditions. This facility is in year-round use by our dealers and customers.

Building the best starts right here.

The products designed and manufactured by Volvo Construction Equipment have their beginnings at the most advanced Research & Design centers in the industry. Volvo CE machines are designed in 11 R&D centers and produced in 15 manufacturing facilities across the world.

The major R&D center and manufacturing plant in the Americas is located in Shippensburg, Pennsylvania. This facility has been in operation for over 30 years and – with its recently added 200,000 sq. ft. expansion – now covers 570,000 sq. ft. on an 80 acre campus. Dedicated work teams and highly advanced technologies and techniques using the Volvo Production System ensure continuous quality improvements, labor savings and cost control to reach the high quality that our customers have come to expect from Volvo.

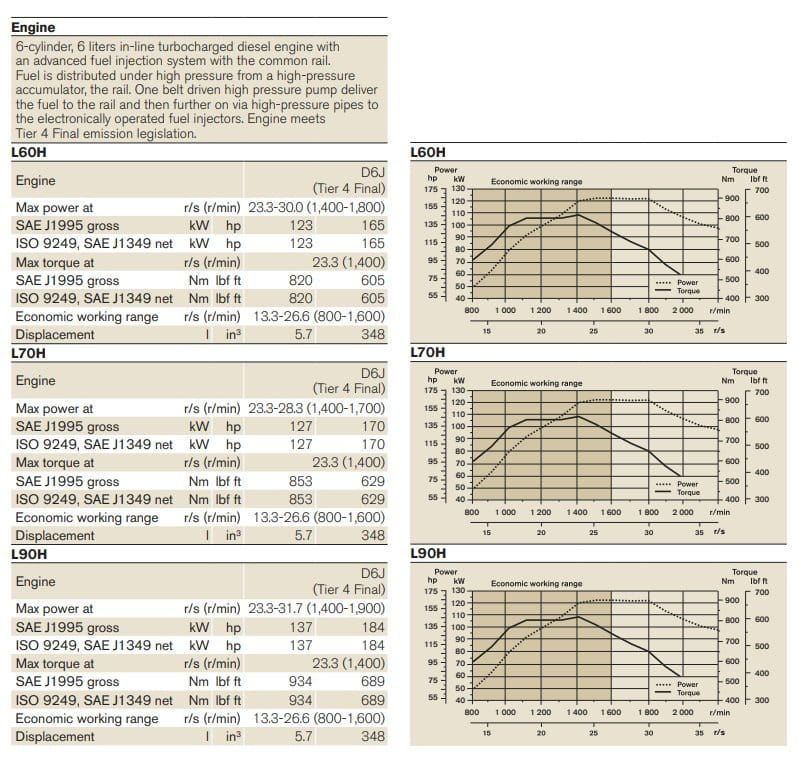

See clearer in comfort.

The Volvo L60H, L70H and L90H wheel loaders are versatile machines that can take on any task with a wide range of perfectly matched attachments. From the comfort of your wheel loader, sit back and enjoy a clear view of the site while increasing your productivity and uptime.

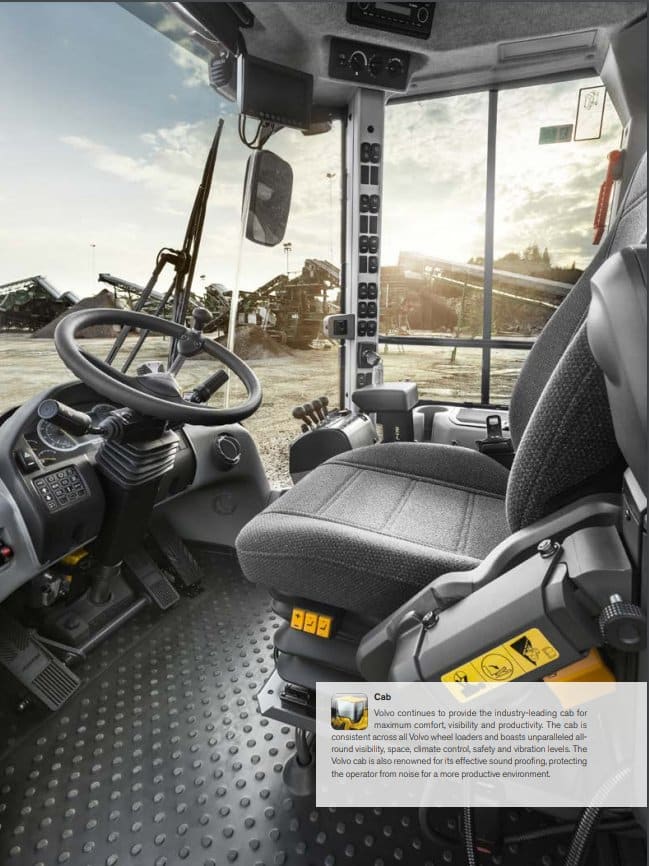

HMI – New display and controls

Operator ergonomics is at the forefront of Volvo’s HMI (Human Machine Interface) design. The information display, controls, setting switches, hydraulic control levers and steering wheel, are all designed and placed in the cab for easy and comfortable operation. The information display informs the operator about all necessary machine information for peace of mind, control and less fatigue. The new display has better visibility even when exposed to direct sunlight.

Seat

The operator’s seat has several adjustment possibilities for maximum comfort. Suspension and damping are adjustable according to body weight and both the seat cushion and backrest can be positioned at various angles. Well placed instruments and adjustable lever console make your long day a lot more comfortable.

Heating, ventilation and air conditioning

The standard Automatic Heat Control (AHC) system ensures a comfortable environment inside the cab. Air conditioning is also available so the operator can work in comfortable conditions, in any climate.

Industry leading air-filtration

Volvo’s industry-leading air filtration system allows 90% of the cab air to be recirculated through the main filter for continuous dust removal and a cleaner environment. The cab air intake is located in a high position where the air is cleaner. An easily replaceable external prefilter effectively separates coarser dust and particles before entering the main filter and cab.

Cab

Volvo continues to provide the industry-leading cab for maximum comfort, visibility and productivity. The cab is consistent across all Volvo wheel loaders and boasts unparalleled allround visibility, space, climate control, safety and vibration levels. The Volvo cab is also renowned for its effective sound proofing, protecting the operator from noise for a more productive environment.

TP linkage

The TP linkage combined with the new and improved Volvo attachment bracket offers industry leading versatility and unparalleled front visibility. The TP linkage combines the benefits of the

Z-bar and parallel linkage to deliver high breakout torque and excellent parallel movement throughout the entire lifting range. The bracket allows attachments to be changed quickly and safely so the machine can perform a wide range of tasks.

An Up-Front Approach

The wheel loaders are especially designed to match a number of attachments so that you can handle a variety of tasks on your job site with the same machine. The TP linkage together with the improved Volvo attachment bracket provides excellent versatility and visibility.

Attachment Bracket

Want to switch between different attachments quickly and easily? Then look no further than the market-leading attachment bracket from Volvo Construction Equipment. The smart design of the interface enables safe connection to a wide range of attachments that meet the International Standardization Organization (ISO) standard.

Double Sealed Joints

The Volvo TP linkage features double sealed joints for all linkage pins. The double sealing system retains lubricating grease and prevents dust or other contaminants from getting in. The double sealing system results in a longer life for the lift arm system. The high quality and durable components last longer, reduce maintenance and increase uptime.

Roll Back Angle

The Volvo TP linkage geometry, along with the Volvo bucket design, provides excellent bucket roll-back angles. The superior roll-back angle increases the amount of retained material in the bucket and keeps the load closer to the front axle for increased stability and less spillage. As a result, the roll back angle increases productivity.

Parallel movement

The TP linkage allows excellent parallel movement, which means the load stays level throughout the entire lifting range. This allows the operator to have full control over the load, which increases safety and productivity

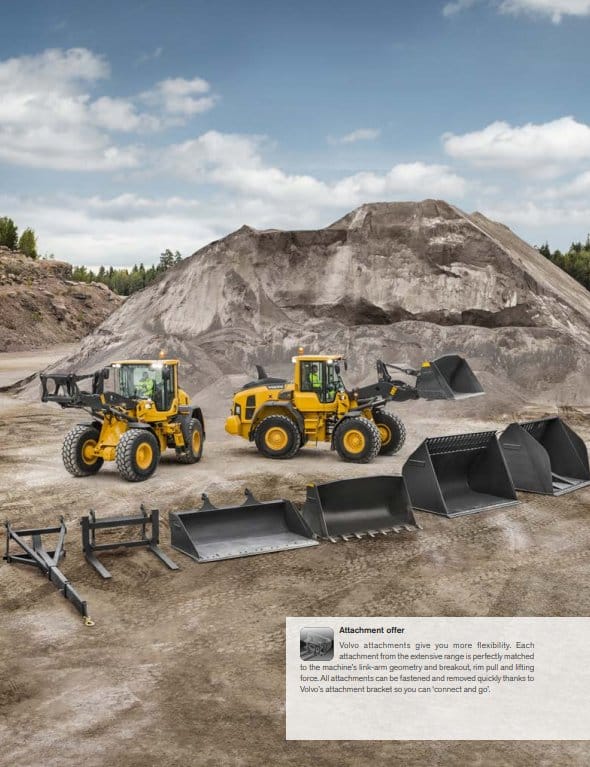

A multiple of talents.

Volvo offers the most durable and effective Volvo attachments, which work in harmony with your machine for increased productivity and versatility. They are designed for improved visibility and ease of use, so you can swap and change your Volvo attachments quickly and safely.

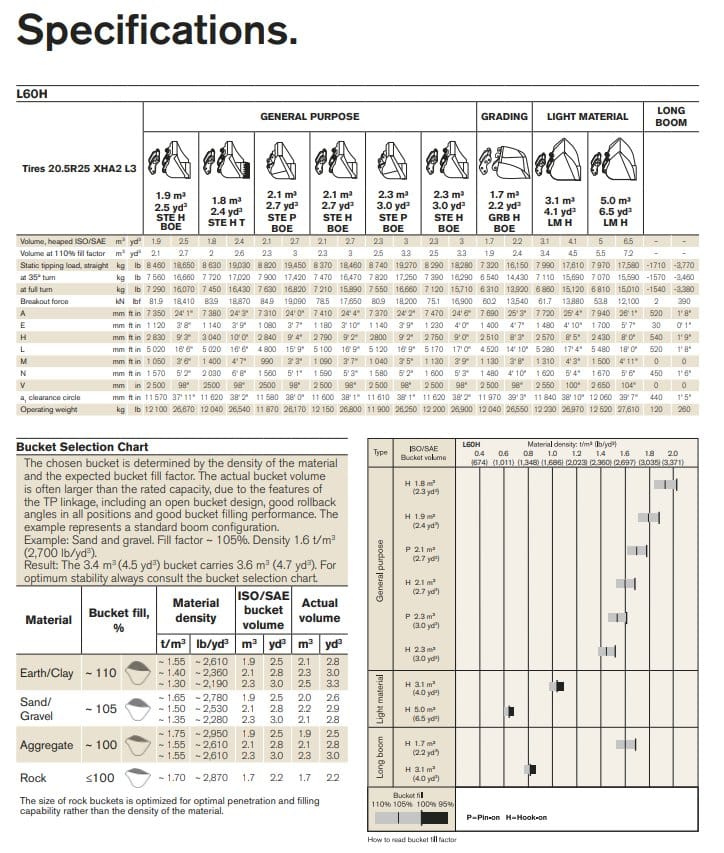

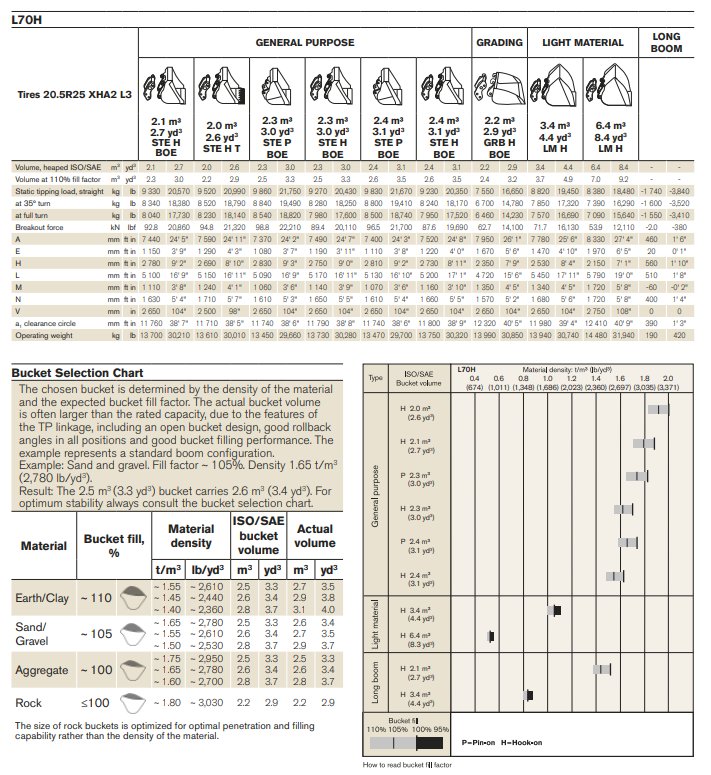

New General Purpose (GP) bucket

The improved Volvo general purpose bucket is designed for higher productivity and increased fuel efficiency. The bucket – when fitted with bolt-on edges – handles loose material, such as gravel and aggregates in both short cycle or load and carry operations. It can be fitted with optional welded teeth and segments to load harder banked material with ease. It provides excellent support on your job site and the wear resistant steel is used in the most exposed areas for increased durability and long life.

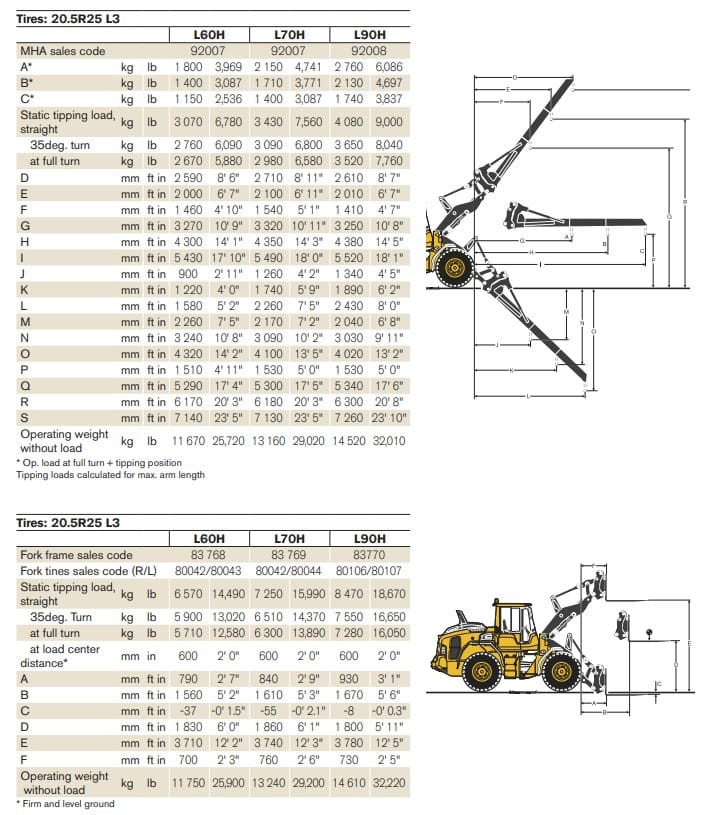

Pallet forks

Volvo’s pallet fork frame with pallet fork tines allow the machine to handle, load and move pallets of building material, drainage pipe, lumber, or loose items around the uneven terrain of a construction site. The Volvo pallet fork and attachment bracket has been designed for industry-leading visibility at different working heights while moving and lifting materials. Volvo’s durable TP linkage, attachment bracket and pallet forks increase safety.

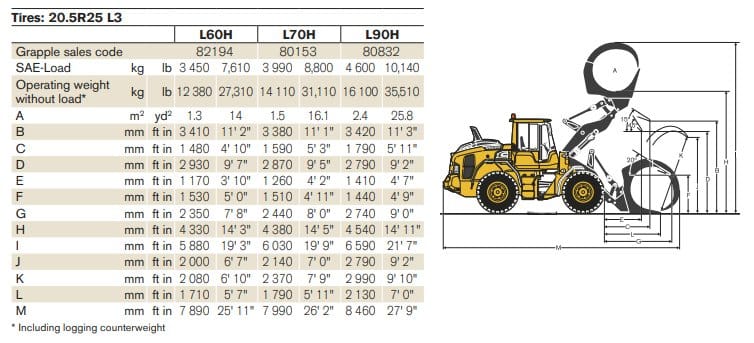

Material handling arm

Volvo’s material handling arm extends your machine’s versatility. Designed to work with Volvo wheel loaders and with an approved lift capacity set for each arm and machine, you’ll know exactly how much you can lift safely. The extendable arm consists of three sections, providing increased flexibility and greater reach. Safety Mechanical stops also prevent the material handling arm from overextending – a safety hook at the end of the arm is fitted as standard.

Light Material (LM) bucket

The Volvo light material bucket with a robust light weight design and high capacity, secures the highest productivity for your machine. The bucket is designed for efficient handling low density material, such as snow, sawdust, wood chips and compost. It’s delivered with a standard bolt-on edge.

Attachment offer

Volvo attachments give you more flexibility. Each attachment from the extensive range is perfectly matched to the machine’s link-arm geometry and breakout, rim pull and lifting force. All attachments can be fastened and removed quickly thanks to Volvo’s attachment bracket so you can ‘connect and go’.

Made to last.

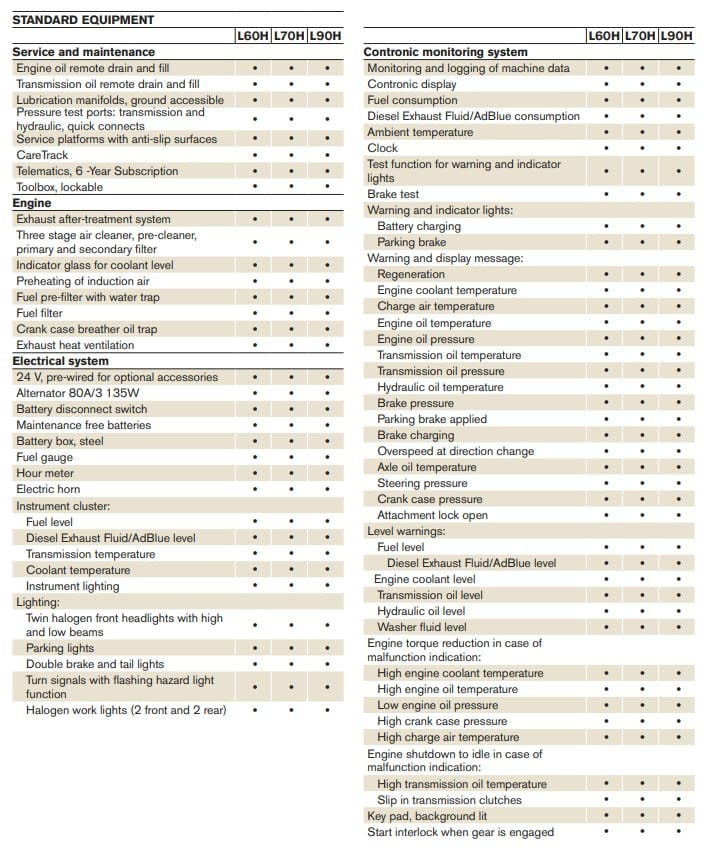

Quality is key at Volvo, which is why only the best components, technology and systems are used in the Volvo wheel loaders. All parts work with each other for increased reliability and a long cycle life, saving you long term costs and downtime.

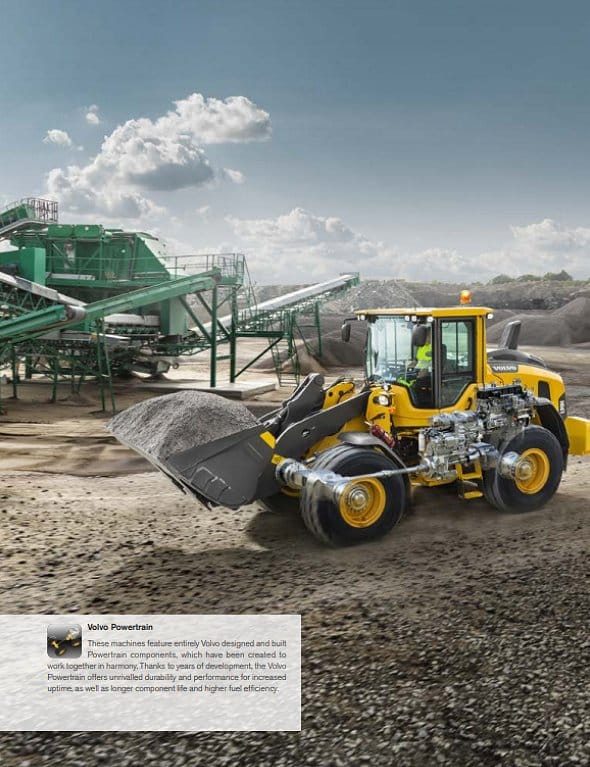

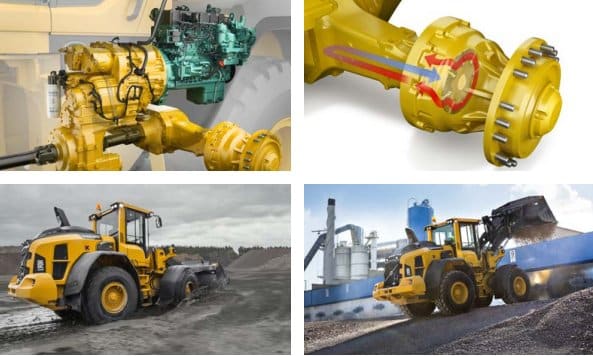

Counter shaft transmission

The Volvo counter shaft transmission offers a heavy duty solution for proven reliability and durability. The machines are equipped with a counter shaft transmission that can endure more stress. Various tailored settings can be selected by the operator to match all applications whether it’s short cycle truck loading or medium to long distance load and carry.

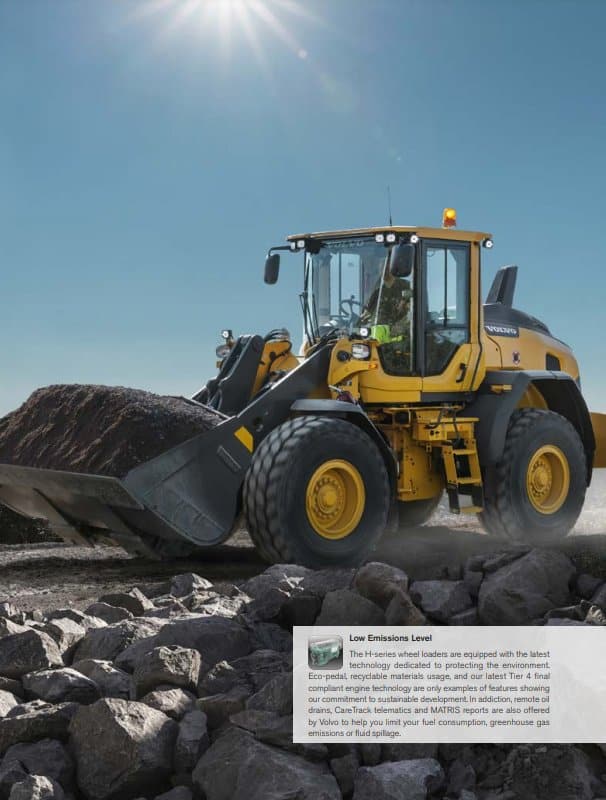

Axles

Volvo axles provide longer service life as a result of the free-floating shaft design, durable components, circulating lubrication oil and wetdisc brakes. The outboard service brakes are easily maintained for greater uptime and can also be easily monitored using the brake wear

Differential lock

The differential lock provide outstanding traction and rimpull on soft and slippery ground conditions. The front axle is mounted to the front frame and equipped with an electro-hydraulically operated differential lock. The differential lock is a dog-clutch type which can secure 100% locking, which minimizes wheel spin and tire wear.

Intelligent hydraulic system

The load sensing hydraulic system increases fuel efficiency and provides perfect control of the load. It also allows for more engine power to be available for rimpull, providing easier penetration for increased performance. With help from the variable displacement piston pumps and precision control levers, hydraulic power is delivered according to demand.

Strongly attached.

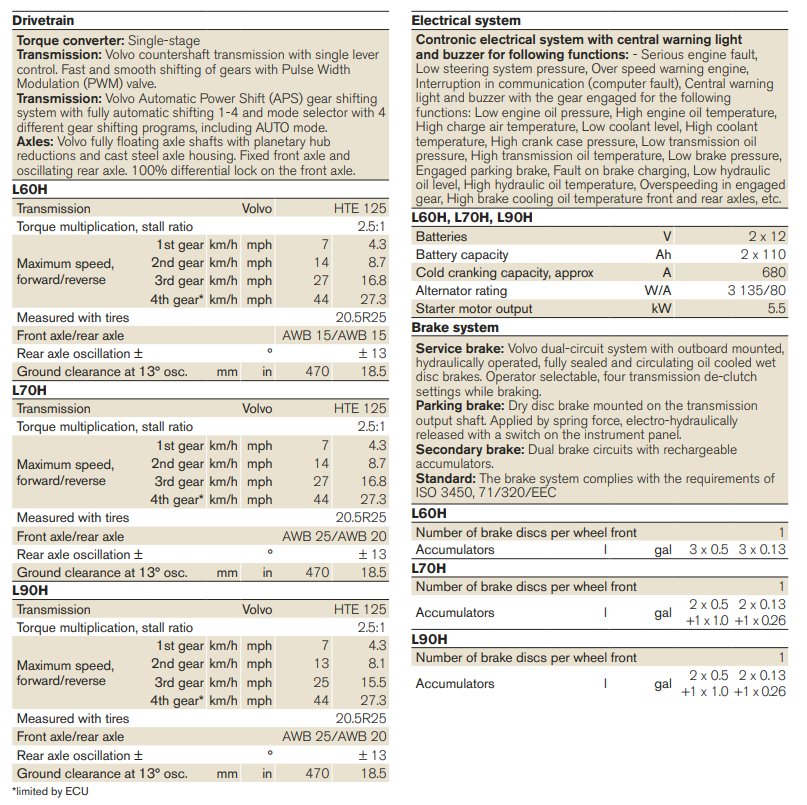

Environmental care is at the forefront of Volvo’s core values and to show its passion and dedication, Volvo thinks about all aspects of the machine which can impact on the environment.

Tier 4 Final

Volvo’s 6 litre diesel Tier 4 Final engine complies with the latest emissions legislation and delivers high torque at low engine rpm. The engine delivers industry-leading performance and impressive fuel efficiency.

Eco-pedal

This unique feature keeps operators aware of whether they are operating in the most economical way in order to increase fuel efficiency. The Eco-pedal with a mechanical push-back mechanism engages when the engine rpm is about to exceed the economic operating range. The operator senses the resistance and then operates within the optimal operating range. If full engine speed is needed, this mechanical push-back mechanism can easily be overridden.

Service access

The service friendly design keeps your routine maintenance quick and efficient. The one piece motorized engine hood opens up at a large angle, providing full access to the engine compartment and engine maintenance points are strategically grouped together for quick and easy service checks. The machine also features fluid drain ports which simplifies the oil changing. This prevents oil spillages that impacts the environment

95% of the machine is recyclable

Planned recycling of the machine is the last stage of its life cycle. Being able to recycle machine parts and materials for use in new Volvo wheel loaders or other products is part of Volvo’s responsibility to environmental care. According to our calculations, the machine is up to 95% recyclable by weight. Volvo thrives to build a sustainable environment and reuse parts whenever possible.

Low Emissions Level

The H-series wheel loaders are equipped with the latest technology dedicated to protecting the environment. Eco-pedal, recyclable materials usage, and our latest Tier 4 final compliant engine technology are only examples of features showing our commitment to sustainable development. In addiction, remote oil drains, CareTrack telematics and MATRIS reports are also offered by Volvo to help you limit your fuel consumption, greenhouse gas emissions or fluid spillage.

An application for any occasion.

Cab

Volvo continues to provide the industry-leading cab for maximum comfort, visibility and productivity.

Human Machine Interface

The information display, controls, setting switches, hydraulic control levers and steering wheel, are all designed and placed in the cab for easy and comfortable operation.

TP linkage

The TP linkage combines the benefits of Z-bar and parallel linkage in one to deliver high breakout torque and excellent parallel movement through the entire lifting range.

Attachment bracket

The Volvo attachment bracket is the most commonly used attachment bracket in the world with a compact and robust design for outstanding visibility.

Attachment offer

Volvo’s wide range of high quality attachments are perfectly matched to the machine’s linkage, hydraulics and driveline to work as one unit and increase productivity.

Eco pedal

This unique feature keeps operators aware of whether they are operating in the most economical way in order to increase fuel efficiency.

Volvo Powertrain

These machines feature entirely Volvo designed and built Powertrain components, which have been created to work together in harmony.

Hydraulic cooling fan

Hydraulically driven, electronically controlled cooling fan, located between the engine and radiator, speeds-up only when necessary to lower fuel consumption and sound levels.

Tier 4 Final/Stage IV engine technology

Volvo’s 6 litre diesel Tier 4 Final/ Stage IV engine complies with the latest emissions legislation and delivers high torque at low engine rpm.

Intelligent hydraulic system

The load sensing hydraulic system increases fuel efficiency and provides perfect control of the load.

Service access

The service friendly design increases your uptime by allowing easy access and quick service.

CareTrack*

CareTrack provides information for better planning and smarter working, including fuel consumption reports, location reports and service reminders.

Low Emissions Level

The wheel loaders are equipped with the latest technology dedicated to protecting the environment.

Lifetime Frame Warranty:

Find out more on volvoce.com/structureandframe

Volvo L60H, L70H, L90H in detail.